“100% visual inspection is being carried out but overlook defect sometimes.”

“Compromised with sampling inspection, but what if found any defective products at customers…”

We often hear voices from customers looking for a better solution for tapped hole inspection.

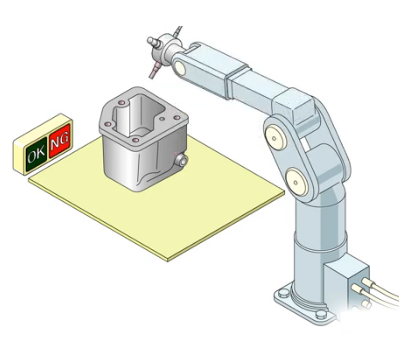

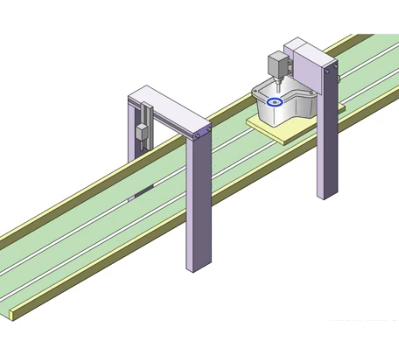

Micro-Fix offers eddy current based tapped hole inspection devices perform at a high speed and high precision.

A simple probe insertion realize automatic reliable inspection at any production site.

- Outline

- Nondestructively detect any tapped hole abnormalities such as wrong hole diameter, insufficient thread length.

- Features

- Reliable operation in the harsh environment as eddy current is never disturbed by oil/ water/ lights.

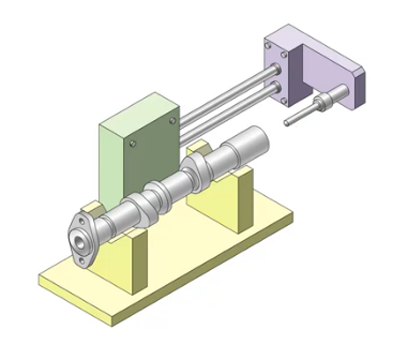

Contactless sensor allows harmless inspection to the object as well as self sustainability.

Sensor size are available from M2.6 or with any modification if necessary.

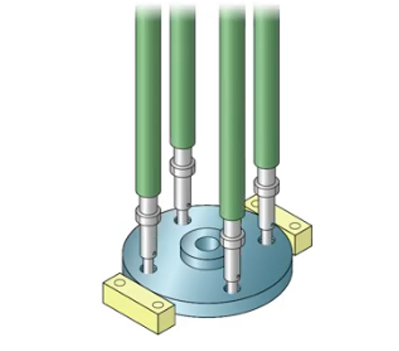

Eddy current tapped hole inspectorMTD-100

Thread presence/ absence detection

wrong pilot hole diameter detection

Insufficient thread length detection

Damaged thread detection

Select from single or multi channel (Optional)

Adjustable setting parameters

Tapped hole inspectorNT-1

Low-priced edition

Thread presence/ absence detection only